Wondering how the production process of a capsule house turns a design into compact living space?Join me as we break down the 9 essential steps, revealing the craft and care that go into each capsule home. Whether you’re a curious individual or looking to invest, I’ve got the insights you need. Ready to dive into the world of capsule house production?

The production of capsule houses involves a series of 9 detailed steps. It all starts with the precise Welding Assembling of metal components and the careful Grinding for a smooth finish. Then, Glass and Interior Assembling come into play, transforming the structure into a fully functional living space. The process also includes the essential Water and Electricity Wiring for services, as well as innovative techniques like using Bending Machines to shape structural elements. This streamlined process ensures that every capsule house is not only efficient and sustainable but also designed with modern aesthetics in mind. These compact living solutions are perfect for individuals and investors looking for accommodations in camping sites, resorts, and beyond.

1. Welding Assembling

Firstly, the Capsule House production process begins with Welding Assembling. This initial stage sets the structural foundation with various metal components expertly joined through techniques like MIG, TIG, or arc welding. The precision here is paramount, as the integrity of these welds dictates the overall stability and safety of the structure. Careful planning ensures each part aligns perfectly for seamless construction, and special attention to the welding environment and equipment maintenance guarantees the highest quality and longevity.

2. Grinding

Then, the focus shifts to Grinding, a crucial post-welding process where surfaces are meticulously smoothed to remove any irregularities. This step, vital for both aesthetic appeal and safety, involves skilled technicians using tools like angle grinders and sanders to create a uniform, smooth finish. This process also prepares surfaces for further treatments like painting or coating, ensuring that these applications are even and long-lasting.

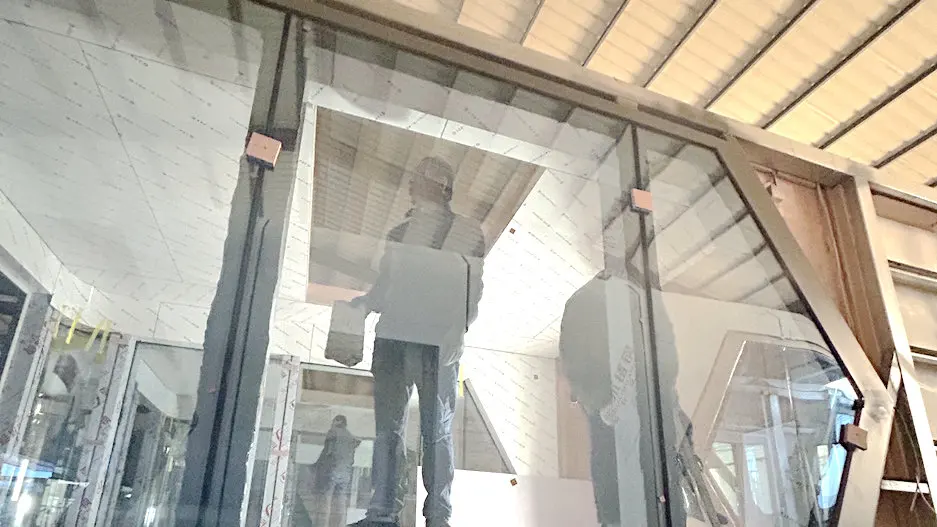

3. Glass Assembling

Next, Glass Assembling takes place, a detailed task involving the careful installation of windows and other glass elements. This stage emphasizes not just the aesthetic appeal, offering natural light and a sense of openness, but also the functional aspects like insulation and durability. Technicians ensure that each glass component is perfectly aligned and sealed to prevent leaks and drafts, contributing to the energy efficiency and resilience of the home.

4. Interior Assembling

Interior Assembling is a phase where the capsule house truly begins to feel like a home. This involves installing walls, floors, fixtures, and all internal features. Each element is chosen for its functionality and space-saving qualities, ensuring that the compact living space is maximized for comfort and utility. This stage requires precise craftsmanship to fit everything neatly into the small area, creating a seamless and cohesive interior that meets the specific needs and style preferences of the resident.

5. Water and Electricity Wiring

Water and Electricity Wiring in capsule houses is a critical step where essential services are installed with precision. This phase ensures that the compact living space is safe, efficient, and comfortable. Expert electricians and plumbers lay out wiring and piping strategically to maximize space and maintain the aesthetic integrity of the design. This involves installing energy-efficient systems and ensuring all fittings are up to code and easily accessible for maintenance. The result is a seamless integration of essential services, crucial for the functionality and livability of the capsule house.

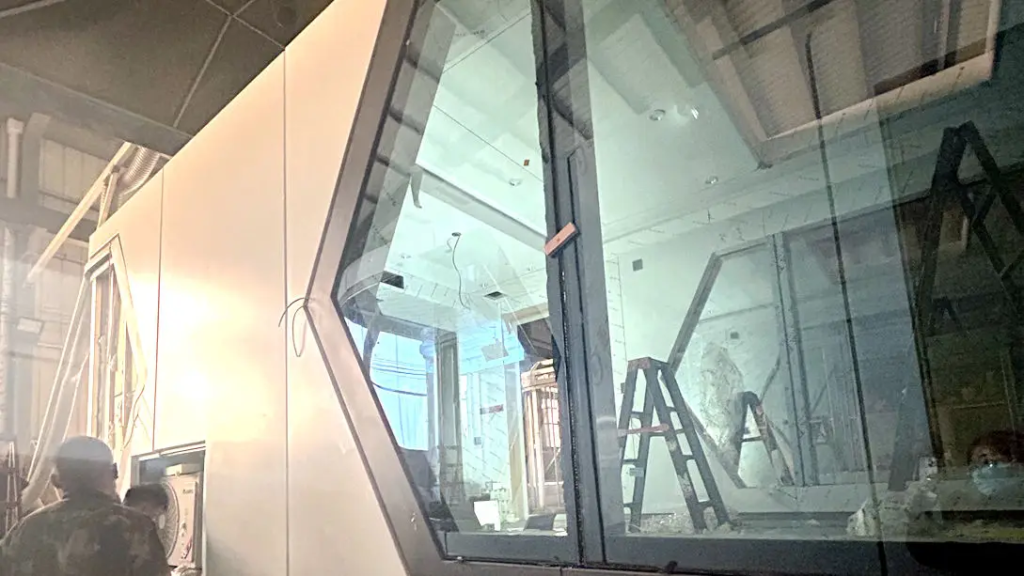

6. Housing Assembling

Housing Assembling is a pivotal stage where the structural components of the capsule house come together to form the complete shell. This process involves precision and coordination as each part, from walls to roof segments, is secured into place. It’s during this phase that the capsule house begins to take its final shape, evolving from individual elements into a coherent, integrated structure. This stage sets the stage for all subsequent interior and exterior finishing work, laying the groundwork for a home that’s not just structurally sound but also aesthetically pleasing and functionally designed.

7. Assembling Line

The Assembling Line is where the capsule house truly comes to life, moving through a carefully orchestrated sequence where different components are methodically added. This production line is the heart of the manufacturing process, designed for efficiency and precision. As the house progresses down the line, each station adds a new layer, from the structural framework to the intricate details of interior fittings. This systematic approach ensures quality and consistency, turning a collection of parts into a fully realized capsule house ready for its final destination.

8. Cutting Machine

The Cutting Machine in the capsule house production process is a vital tool used to precisely cut materials to the exact specifications required for a perfect fit. This sophisticated machinery is integral to ensuring that each component of the house aligns seamlessly, contributing to the overall structural integrity and aesthetic quality of the finished product. Its precision allows for intricate designs and efficient use of materials, reducing waste and ensuring every piece is optimized for its purpose in the construction process.

9. Bending Machine

The Bending Machine is crucial in shaping metal components that contribute to the structural elements of the capsule house. It’s not just about bending metal; it’s about precision and consistency, ensuring that every curve and angle contributes to the overall integrity and aesthetic of the home. This machine allows for complex designs and contributes significantly to the durability and stability of the structure, ensuring that the capsule house not only looks good but is also strong and safe.

Conclusion

These 9 meticulous steps, from welding to bending, are the backbone of capsule house construction, showcasing the precision, innovation, and quality that goes into creating these modern, compact living spaces. Each phase reflects a commitment to excellence and sustainability, ensuring that every capsule house is not just a structure, but a well-crafted home ready to inspire and transform living experiences.

For more details or to embark on your innovative compact living project, whether for personal use, a camping site, or a resort, feel free to contact us. We’re here to guide investors and homeowners alike, every step of the way.